Brewer Science employees already see how little goes to waste in their work environments.

Now, they have further proof of that achievement.

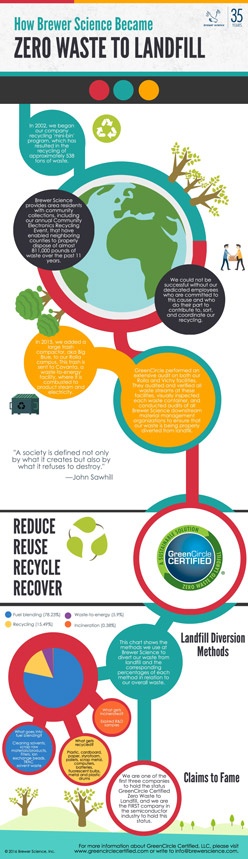

Earlier this year, Brewer Science facilities in Rolla and Vichy earned Zero Waste to Landfill Certification after an in-depth audit confirmed they contribute zero waste to landfills. Brewer Science is one of only three companies worldwide, the only company in Missouri, and the only one in the semiconductor industry to earn the certification from third-party firm GreenCircle Certified LLC.

Earlier this year, Brewer Science facilities in Rolla and Vichy earned Zero Waste to Landfill Certification after an in-depth audit confirmed they contribute zero waste to landfills. Brewer Science is one of only three companies worldwide, the only company in Missouri, and the only one in the semiconductor industry to earn the certification from third-party firm GreenCircle Certified LLC.

That’s huge in a nation still widely struggling to control its waste and landfill issues. One report shows the U.S. is still filling landfills with five pounds of trash per person, per day. And the nation’s fragmented waste management system was able to achieve only a 34 percent recycling rate between 2013 and 2015.

In comparison, Brewer Science is able to blend 78 percent of its waste into fuel, recycling another 15 percent and converting nearly 6 percent more into energy, with less than 1 percent requiring incineration. Remarkably, the company has maintained that zero-waste pattern for quite some time and is determined to stay zero waste to landfill.

“We’re proud of the results our health, safety, security, and environmental management efforts have made on our internal and external communities,” says BSI President Dr. Terry Brewer. “We continually seek ways to improve.”

True Blue A major factor in Brewer Science’s zero-waste record has been “Big Blue,” a giant compactor installed last year at its Rolla facility that collects non-recyclable waste that would otherwise be landfill-bound. Once compacted, the materials are taken to the Covanta Energy combustion facility and converted to steam and electricity. The resulting energy fuels about four houses or powers about 480 light bulbs monthly.

We’re cool with fuel Last year, the company converted a record 520,000 pounds of hazardous waste into fuel used to replace coal and natural gas in cement kilns. The fuel is made by blending high-BTU liquid solvent waste with high-BTU solid waste at a highly controlled fuel blending facility. The blended fuel is then sent to approved cement kilns.

Recycling rocks Another Brewer Science achievement has been its company-wide recycling program, which collects and processes recyclables from various plant locations. Even packaging elements and pallets are shredded and composted. Employee participation has helped lead to a whopping 597 tons of recycled waste since 2002. Through community partnerships over the past 11 years, the company has also provided volunteers and hired disposal companies for the collection of nearly 811,000 pounds of appliances, electronics and tires from residents in Phelps County.

And in 2015 alone, it was able to recycle some 100,000 pounds of cleaning solvent.

But wait, there’s more

In other examples of Brewer Science’s ongoing environmental efforts:

- The company achieved 94 percent of its internal Green Program goal for 2015, partly by retrofitting utility systems to be energy efficient.

- To date, Brewer Science’s Green Program has conserved 498,400 gallons of water, 308,325 kWh of electricity and 8,800 therms of natural gas.

- Brewer Science successfully reduced chemical spills and exposure by 35 percent between 2014 and 2015.

- Reams of paper used per employee at Brewer Science dropped from about 5.5 to 3.5 between 2013 and 2015.

- The company’s per-employee investment in solid waste disposal costs was down to nearly $45 last year.

GreenCircle follows guidelines set by the Federal Trade Commission to evaluate the validity of manufacturers’ environmental claims. During Brewer Science’s certification, it audited and verified all company waste streams and downstream material management organizations, and virtually inspected all waste containers.

Brewer Science has previously won recycling awards through the National Recycling Coalition, the American Forest & Paper Association and the Ozark Rivers Solid Waste Management District. The company has also achieved Bureau Veritas certification and meets environmental standards dictated by its ISO 9001, ISO 14001 and OHSAS 18001 certifications.

“We continue to challenge ourselves to find additional opportunities to reduce our environmental footprint,” notes Dr. Brewer. Download Brewer Science’s 2016 Annual Environment Report for more information.

Subscribe to Our Blog