Dr. Terry Brewer and his cohorts founded Brewer Science with an extraordinary idea, and through the years that tradition of continual experimentation, innovation and the pushing of boundaries has become a major component of the company’s success.

A company culture that encourages and supports new ideas from multiple sources — including the minds of any and all team members — has served Brewer Science exceptionally well in its 36 years, allowing it to develop myriad products used to improve tablet computers, smartphones, digital cameras, televisions, LED lighting and other devices. Its dedicated work has made devices smaller, thinner, faster, smarter, cheaper, more powerful and more portable, and through the years it’s been responsible for more than 90 U.S. patents, 250 technical publications and more than 25 industry awards.

“Any Brewer Science team member can submit product ideas for evaluation and consideration to enter our development pipeline,” notes Laura Grubbs, Brewer Science’s Business Operations Manager-WLP Materials Division. “And all ideas are welcomed and evaluated within our many cross-functional work teams. Working within a team fosters innovation by considering different perspectives and having a sounding board to discuss ideas thoroughly.”

Brewer Science’s marketing and communications department asked Grubbs more about how new concepts are vetted and developed at her level.

Q: Where do most ideas for Brewer Science products come from?

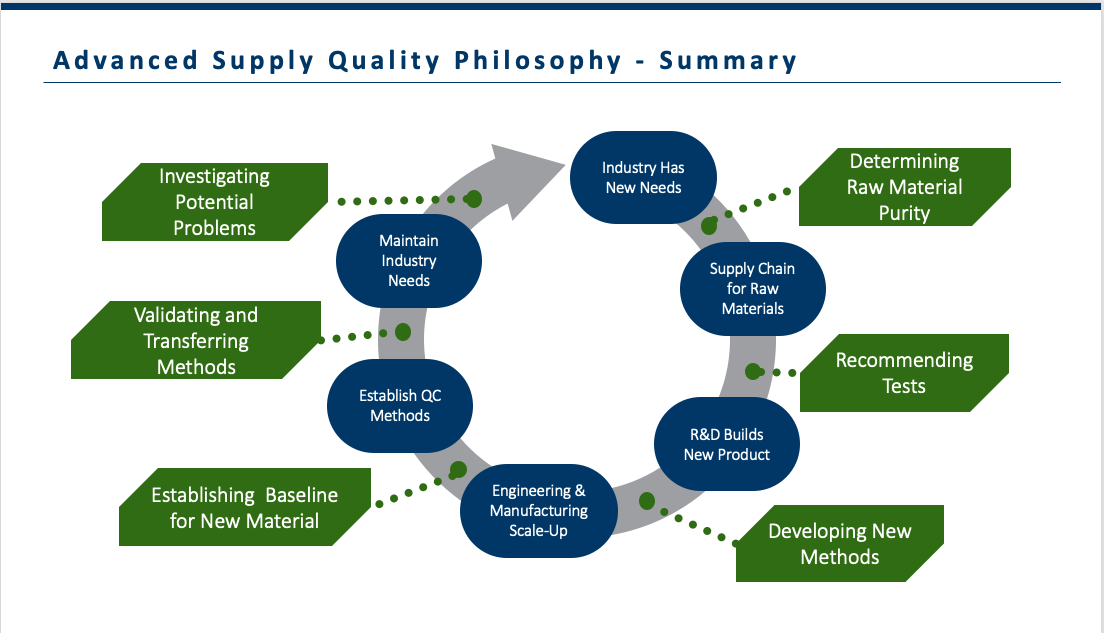

A: Our research and development teams often develop really interesting materials that later find applications within the industry as products. We also work closely with customers to help meet their critical performance requirements, and within those working relationships, many amazing ideas originate. New products are not the only end point for great ideas. Great ideas can help us do what we do better. Innovation can come in the form of continuous improvement (improved filtering, lower defects/impurities, improved process capabilities), manufacturing innovations (including automation) and advancing metrology capabilities.

Q: How long does it typically take for a new Brewer Science product to develop from conception to marketing?

A: It takes approximately 18 months, but the timeline is very dependent on the specific product. We are forward-thinking just like our customers and the industry we serve. To meet the needs for the next upcoming project or application, we need to understand performance requirements and start working early so our materials are characterized, qualified and can be made at scale when they are needed. Sometimes that process can take years. Our involvement with industry consortia is critical to understand those needs and requirements early, which helps shape our product development pipeline.

Q: Say one of your engineers has a new product idea. How does he present it and how is it vetted to determine whether it’s feasible? What factors are considered? What kind of market research is conducted?

A: An engineer could bring up a new product idea in a team meeting or submit it as an idea internally through our product development pipeline tool. Once it is submitted/discussed, it would be evaluated for technical, legal and business feasibility. The Competitive Intelligence (CI) team evaluates the intended market to verify it’s healthy and set to sustain growth.

Q: Once Brewer Science decides to move forward with a product, what happens next?

A: The product then enters the product development pipeline. During that process, the technical aspects of the project are reviewed regularly; the material requirements become more stringent as the product continues through the development process. Our Corporate Management Team also regularly evaluates the platforms in the development pipeline to ensure they still align with our corporate objectives and business opportunities and are competitive in the market.

Q: Which stage of development tends to be the most challenging?

A: The most challenging stage is probably the engineering scale-up. Unlike baking cookies where it is simple to double (or triple!) the recipe while always getting consistent results, our specialty materials are much more complex. Many factors affect the quality and key performance characteristics that make that formulation a novel material. It is imperative we make a material's performance and quality consistent from small scale to mid-scale up to high volumes, so those prize-winning attributes are not altered. Our chemical engineers work closely with chemists, quality teams, process engineers and manufacturing to ensure the material remains the same throughout the development process.

Q: What is the most rewarding?

A: That’s probably dependent on who you ask. From a chemist’s perspective, proof-of-concept is probably very rewarding because he or she has created a material that proves the concept can be achieved. For a chemical engineer, the scale-up phase is very rewarding because he or she has engineered a way to make more of that novel material while making sure it’s the same as it was during smaller-scale development. As a company, we always feel rewarded when we launch a material into the market; it’s the culmination of a lot of hard work from every member of our team to see an idea fostered from its inception into a commercially available product.

Q: How often are potential new products abandoned because of stumbling blocks during the development process? What are some typical roadblocks?

A: A healthy product development pipeline should act as a funnel. Not every material or idea that begins the process will become a final commercialized product. Throughout development, many factors need to be continually evaluated. Does this material platform meet a need? Can we make this material reproducible at multiple quantities and at superior quality? Does this platform fit well within our strategic roadmaps and align with our core values as an innovative company? We want to make sure we invest resources into the right products that will hit the market at the right times to be a solution to a need for our customers.

Q: At what point do other Brewer Science departments such as packaging, marketing and sales get involved in the development of a new product?

A: Each stage of the development process involves our packaging, marketing and sales teams. Our sales team and account managers are imperative to the feedback loop we rely on while creating materials. Without alpha partners and the feedback from our customers about what key characteristics they need from new materials, it would be almost impossible to align our products to the industry’s needs.

Q: How difficult is it to maintain secrecy when it comes to the development of proprietary new products, and how does Brewer Science do that?

A: We rely heavily on our Intellectual Property (IP) department to help ensure our ideas and hard work are protected. Our specialists there are amazing at understanding patent law, where there is space for new materials and where there might be legal saturation. Our Information Technology department also works hard to make sure our internal systems are secure for internal communication and collaboration.

The ability to think beyond the traditional to the next stage of possibility will likely always be a keystone of Brewer Science’s culture, and a continual gateway to its success.

“For the raw materials we create to reach their potential, they must be connected with creativity and imagination,” Dr. Brewer once told the St. Louis Business Journal. “The process is reciprocal, as the products themselves can also inspire creativity and imagination.”

Subscribe to Our Blog