There you are, working away at your desk when that dreadfully random thought pops into your head: “Man. I wonder if those eggs in my refrigerator are still OK.” We’ve all been there. Naturally, you reach for your smartphone and open up the app connected to your egg tracker to see how they are.

There you are, working away at your desk when that dreadfully random thought pops into your head: “Man. I wonder if those eggs in my refrigerator are still OK.” We’ve all been there. Naturally, you reach for your smartphone and open up the app connected to your egg tracker to see how they are.

That’s right. You can use your smartphone and an app to check the status of eggs in your refrigerator.

We don’t bring this up to make you think you need a smart egg tracker (trust us, you don’t). We bring this up to demonstrate there’s a seemingly endless number of devices and processes that are interconnected, whether through the Internet or an internal network. Anything from electrical outlets and thermostats to smart locks and home security systems can be paired with and operated by a remotely connected device, giving you complete data transparency and logging capabilities. These features have now been extended to Brewer Science’s benchtop equipment.

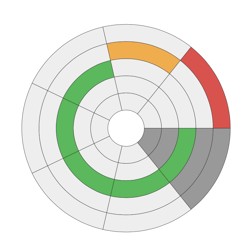

Brewer Science has revamped its line of Cee® benchtop equipment and is set to release the DataStream™ system on its new Apogee™ tool bundle. DataStream™ technology gives you access to all of your connected Cee® Apogee™ manufacturing equipment in one place to track, access, and modify your systems via a website. And we’re not just talking about simple start and stop functions. This technology will give manufacturers the ability to process and visualize data in real time and search and export that data to a number of different formats.

It doesn’t stop there, either.

Manufacturers can create and deploy multiple recipes and configurations to numerous clean room tools without having to gown up, and they can even monitor the clean room environment for air temperature and humidity without being near the room at all. Before and after features are a given, and DataStream™ technology even allows remote control to be seamlessly passed to a user in the lab to actually perform the process.

Our favorite feature, however, might be the DataStream™ system’s unique ability to meticulously log data, recipes, and settings, backing them up for better insights and improved decisions in the future. Remember that batch of silicon wafers that failed QC last week? You can go back and check every single factor (including the details of the recipe and process parameters, who was running the tool, or even ambient temperature and humidity in the room) to see what went wrong and why, all through a simple, easy-to-navigate interface.

Talk about strength in numbers.

No matter the size or setting of the operation, and no matter where you are in relation to it, DataStream™ technology could mean tremendous things for the semiconductor industry. Higher productivity, more comprehensive data, and better decisions are just the beginning.

Check out Brewer Science’s lineup of manufacturing equipment and just imagine the endless DataStream™ technology connection possibilities.

Subscribe to Our Blog