Protecting our environment and conserving resources are essential to running a successful and mindful business, but how do you make this part of your organization’s mission and vision? The key to building a culture of environmental responsibility begins with the commitment and support of leadership and engagement of all employees. Engaged employees are a key source for ideas and serve on teams that assure regulatory compliance and build environmental projects. In this blog, we explore how Brewer Science has made environmental friendliness a part of everyday life for all employees through the following projects: Green Circle Zero Waste to Landfill certification, solvent reuse and Renewable Energy Certificates (RECs).

GREEN CIRCLE ZERO WASTE TO LANDFILL CERTIFICATION

Every year, tons of waste ends up in landfills and get broken down into compounds, such as methane gas, that can create air pollution. By sending our non-hazardous waste to a waste-to-energy incinerator, Brewer Science is able to decrease the amount of coal needed to produce energy, and in turn, reduce air pollution.

When installing our non-hazardous waste compactor, we looked for a certification to bring awareness to work about what Brewer Science does to positively impact the environment. With the completion of two years as “zero waste to landfill,” the culture of environmental responsibility continues to be a way of life at Brewer Science.

We have multiple projects surrounding our environmentally responsible standards, including switching from disposable water bottles to reusable glassware. After three years, the momentum that this certification has created will continue to embed itself into the company culture.

SOLVENT REUSE PROJECT

Solvents, after being used by one industry, may be what another industry needs in one of their own processes. This adds to the useful life of the solvent so that it doesn’t go to waste after a single use. Brewer Science employees implemented the following approach for this project:

- Identified a solvent and a reuse customer

- Tested solvent for consistency

- Developed a specification

- Generated a safety data sheet

- Qualified customers

- Tracked shipments

- Worked with manufacturing to qualify other solvents for reuse

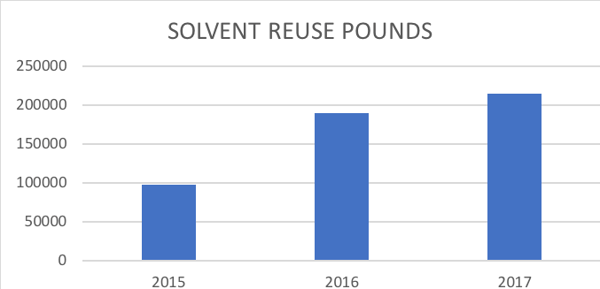

Shows the amount in pounds of solvent that was reused for the past 3 years

WIND-GENERATED RENEWABLE ENERGY CERTIFICATES (REC)

Rolla Municipal Utilities first offered RECs in 2016 and Brewer Science, excited about the opportunity, was the first company to purchase them. Since that time, Brewer Science has purchased an average of 500 RECs per month. By purchasing RECs, we are able to provide capital for renewable energy suppliers like Marshall County Kansas wind farm.

The Marshall County Kansas wind farm generates renewable electricity that it feeds into the power grid that supplies Rolla Municipal Utilities. One REC is issued to the wind farm when one megawatt-hour (MWh) of electricity is generated and delivered to the electricity grid. The wind farm makes the REC available for purchase by customers who want to support the growth of renewable energy. The RECs are managed through the North American Renewables Registry (NAR) and Missouri Public Utility Alliance.

Brewer Science is always looking for ways to build on the success of past projects to sustain this culture of environmental responsibility. New projects include energy efficiency, renewable energy, vehicle charging stations, green chemistry and waste neutralization.

To stay up to date on industry hot topics, subscribe to the Brewer Science blog.

Subscribe to Our Blog