Condition monitoring is necessary for businesses that look to increase efficiency and productivity, while minimizing loss of time and capital. This can be achieved through continuously tracking and analyzing data and reacting accordingly—resulting in process efficiencies. Brewer Science designs specialized sensor systems specific to our clients' needs by combining materials science expertise, printed flexible electronics technology, and firmware development solutions to deliver flexible hybrid electronics (FHE) products that deliver actionable data required for today’s sophisticated IIoT environments.

What is an FHE Foundry?

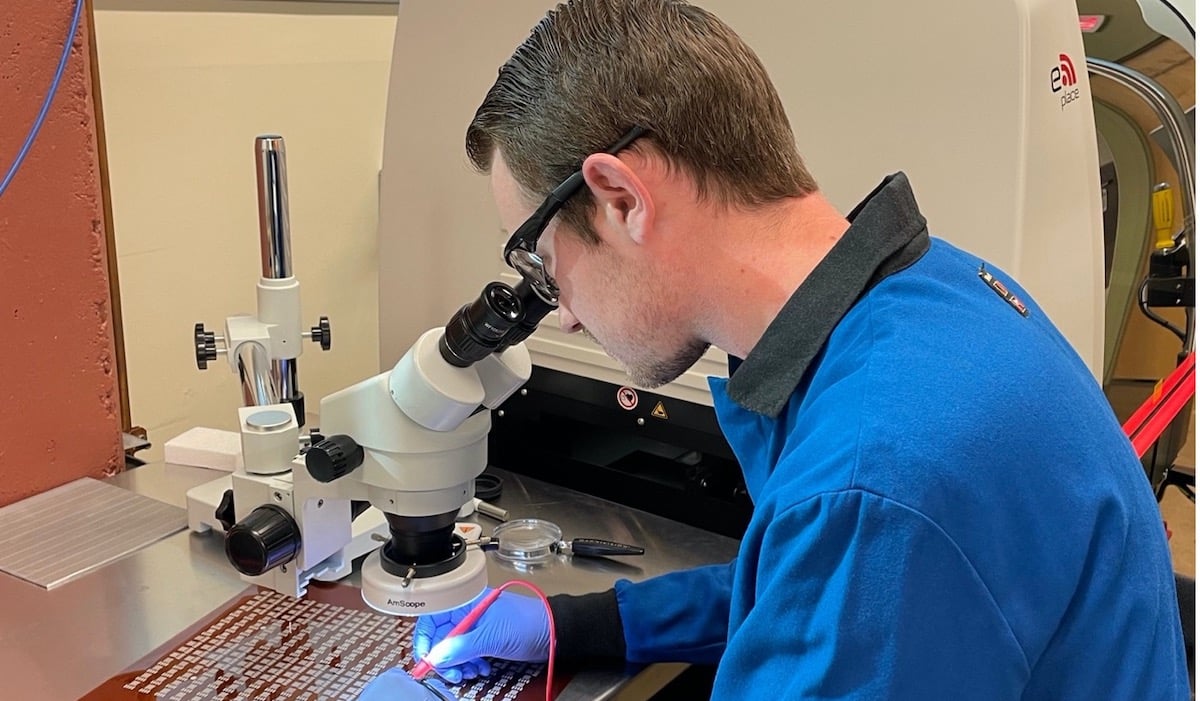

FHE is the abbreviation for flexible hybrid electronics, an industry term for flexible and stretchable devices created by combining printed and advanced CMOS-based components on a flexible substrate. Since FHE is an emerging area with significant room for innovation, the FHE Foundry at Brewer Science brings newfound discoveries in the applications and potential uses of FHE electronics. Brewer Science offers FHE Foundry services for pilot-scale print services with design, customized prototyping, process development, manufacturing, and testing, leading to conversion to high-volume manufacturing.

Who uses FHE Foundry?

FHE makes customization easy and innovation endless. It carries the advantage and ability to integrate traditionally known, trusted technologies into unique and sometimes difficult locations and processes. The ability to customize FHE solutions for a specific process or piece of equipment allows a company to focus on actionable data for process optimization, rather than manual management of technology in its operations. We work with our customers to create specialized technology directly addressing their needs. We are currently seeing growth and increased interest in the markets of industrial and environmental monitoring, resource tracking and management, and consumer electronics such as healthcare devices and wearables. One of the amazing facets of FHE is its ability to provide tailored solutions for nearly any market imaginable.

How does FHE Foundry impact companies?

Customized FHE sensor solutions provide the ability to control operational variables and collect actionable data never logged in an operation before. When combined with a new level of data analytics and machine learning, this new degree of information gives a facility’s team the actionable information needed to make improved operational decisions.

Brewer Science is currently making groundbreaking discoveries in FHE deployments in water, valve, pump, force, and temperature monitoring. This technology platform allows facilities to monitor factors like environmentalfecting production and yield, improve preventative maintenance programs, reduce mach conditions afine downtime, and makes possible the rapid calibration and reporting of manufacturing device and process performance and its impact on finished goods. You can learn more about Brewer Science’s FHE capabilities in this virtual tour.

You can read more about our expansion of the printed electronics unit to include Smart Devices and Printed Electronics Foundry in the recent press release.

Subscribe to Our Blog