There seems to be a preconceived notion out there that you can be either pretty good at many things or extremely proficient at one. You may recognize the popular title given to one who embodies this belief: “Jack of all trades, master of none.” The only way to achieve true proficiency, according to this reasoning, is to devote enough time and energy to something that it’s impossible to achieve that same level of proficiency anywhere else.

Flexible sensors happen to be an exception.

They’re lightweight, consume minimal power and just so happen to function tremendously well, no matter the application. You can confidently call them a master of all trades. And while the ceiling of their benefits has yet to be reached, there is still plenty to be excited about right now.

They’re...well…flexible

Though it may seem redundant, the flexibility is one of the most important and unique features. Though there are many possible applications of this feature, it’s having an especially big impact on robotics.

An often overlooked feature of these flex sensors is their vibration-sensing capability. This is exciting for the world of manufacturing.

When working properly, each machine a manufacturer uses operates at a resonant frequency, a vibrational “sweet spot,” if you will. When that machine’s resonant frequency falls out of that sweet spot (or even its range of frequencies), the flex sensor can instantaneously detect the abnormal vibration and either terminate or modify the action.

They’re extremely efficient

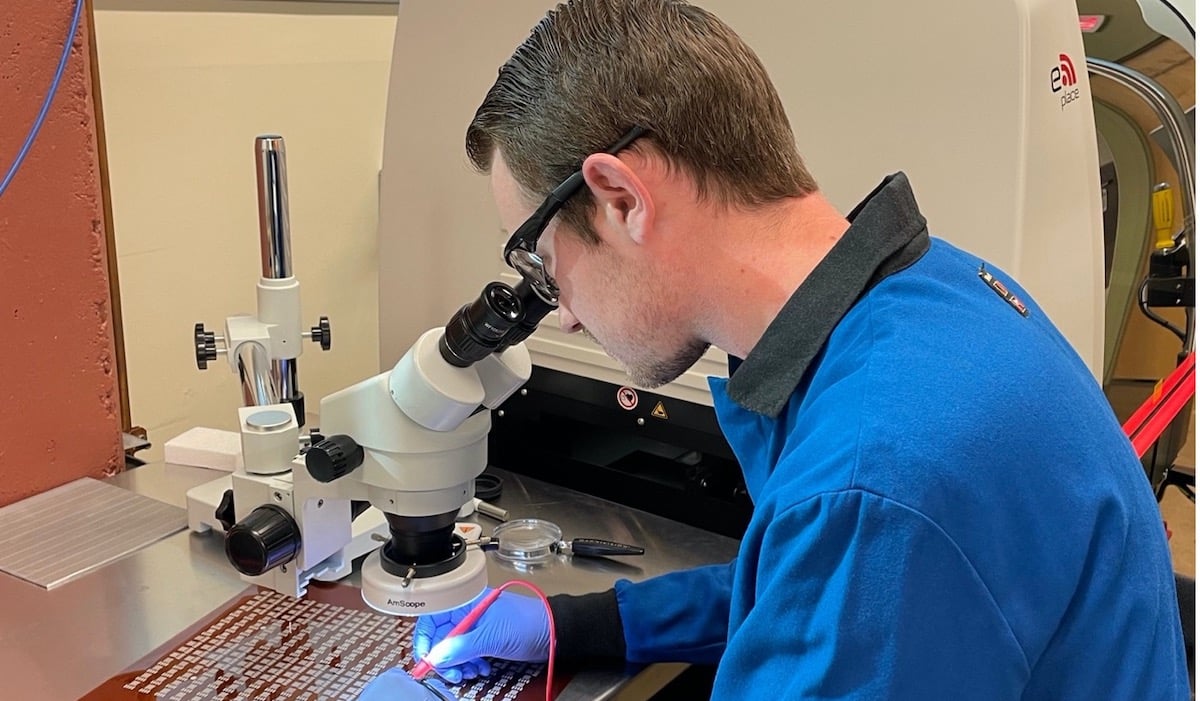

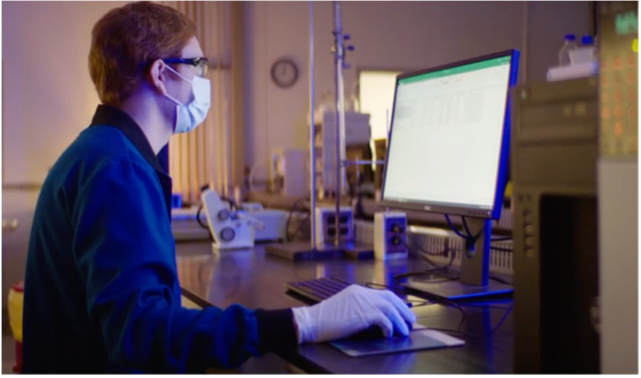

The Brewer Science Inflect™ Flex Sensors are in a class of their own when it comes to efficiency. They are extremely sensitive, lightweight and they operate on relatively low power.

This unmatched sensitivity translates into some impressive functions. They can be used to measure the structural health of new infrastructure designs, reacting to shifts of even a single degree of bend. The sensors can track and monitor changes in air flow in HVAC lines, keeping tabs on important ducts and pipes.

This sensitivity also primes them to shine in things like wearables and MEMS devices where space, weight and power sources are all at a premium.

We’re impressed and excited every day by the capabilities of these tiny little sensors. How they'll be used next, we can only speculate. But one can only assume they'll master whatever task is at hand. Contact a Brewer Science device expert to learn how our technology fits into your process.

Subscribe to Our Blog